About AGC Ceramics

Refining Ceramic Materials and Applications

We consistently consider in the customer's perspective, acting with sincerity and pride to deliver value that exceeds expectations.

- Technological Innovation since 1916

-

Over 100 years

-

AGC Inc. began refractory manufacturing as a core business more than 100 years ago

- Global Share of High Zirconia Fused Cast Refractories

-

No.2

-

in the world

(based on sales / our own research)

- Leading Company

-

in Refractories for Glass, Incinerators, and Aluminum

Our business is refractories, fine ceramics, and engineering within the AGC Group.

Why Choose AGC Ceramics?

Social Challenges and Customer Needs Surrounding Us

Social Challenges

- Carbon Net Zero

- Reducing Environmental Impact

- Developing Social Infrastructure

- Declining Labor Population

Customer Needs

- Reducing GHG Emissions

- Achieving a Circular Economy

- Reducing Lifecycle Costs of Facilities

- Advanced and Efficient Operations

- Labor-saving & Shortening Construction Time

AGC Ceramics Solutions—Proposals Based on Extensive Experience and Expertise—

- 01Optimal Product Proposal Capability

From our extensive lineup of fused cast, monolithic, bonded refractories, and fine ceramics, we propose the best products tailored to our customers' needs.

- 02Development Capability for Diverse Customer Needs

As society evolves, we rapidly and flexibly develop products and services to meet changing and diversifying customer needs, contributing to solving social challenges together with our customers.

- 03Lifecycle Support for Glass Melting Furnaces

Utilizing our wealth of experience and technical knowledge, we provide comprehensive solutions for the design, construction, and operation support of bottle glass melting furnaces.

AGC Ceramics Product & Service Solutions

By combining manufacturing expertise—including technology, development, quality control, and capability —with cutting-edge data and digital technology, we co-create new value with our customers.

Continuously Chosen Refractories & Fine Ceramics Products

High Zirconia Fused Cast Refractory ZB-X950 Series

High Zirconia Fused Cast Refractory ZB-X950 Series are critical components for glass melting furnaces requiring high quality. Exceptional properties that minimize defects in molten glass, earning continuous selection by customers. The lineup is expanded to meet new customer needs and optimal material selection for different glass types.

Monolithic Refractories Asahi Caster® Series

Monolithic Refractories Asahi Caster® Series - A broad lineup of products developed with selected raw materials and proprietary formulation technology tailored to customer requirements.

Bonded Refractories for Cement Kilns

Providing Refractory Total Solutions to the cement industry worldwide.

Fine Ceramics

Meeting customer needs with Fine Ceramics made from unique materials and special manufacturing methods.

Comprehensive Lifecycle Support Technology for Glass Melting Furnaces

- Glass Engineering: Integrated support for design, construction, and operation of glass melting furnaces

- Engineering and support systems to optimize the lifecycle of customer facilities

Unique Materials and Engineering for Energy Saving

- Fuel efficiency is enhanced through the use of High Thermal Insulation Ceramics Asahi Caster TMT Series

- Fuel cost reduction with Ecolead Furnace for glass melting furnaces

- Silicon Nitride Bonded SiC Tiles for efficient heat recovery in boilers

Unique Materials and Construction Methods for Labor-saving & Shortened Construction Time

- Dense Dry-Gunning Castable Asahi Caster GRAM Series for labor-saving and shorter construction periods

- Rapid heating castable Asahi Caster QD Series for reduced drying time in monolithic refractories for incinerators and aluminum melting furnaces

AGC Ceramics Vision

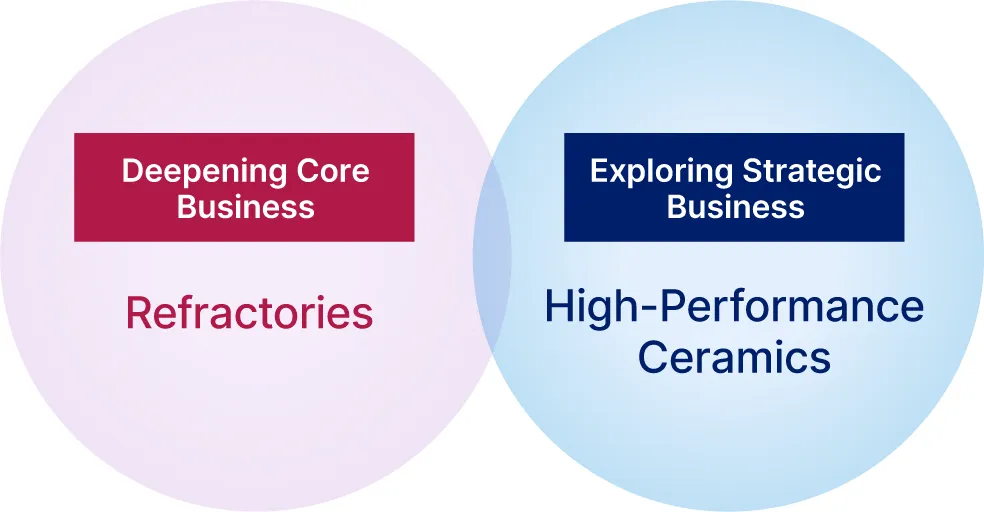

Ambidextrous Management: Deepening Core Business & Exploring Strategic Business

AGC Ceramics aims for sustainable business growth through ambidextrous management —deepening our core business and exploring new strategic business.

- Deepen our core business for high-temperature processes

- Strategically expand in two directions:

- Expanding business domains beyond temperature boundaries, into areas such as energy and semiconductors, in line with macro trends

- In our core business, developing new value by combining data and digital technology with services