Glass

Refractories and Engineering Supporting Stable Operation and Productivity Improvement of Glass Melting Furnaces

We are a group company of AGC Inc., the world’s largest glass manufacturer.

With over 100 years of experience in refractory production and more than 50 years of engineering achievements, we are proud of our long-standing expertise.

The combination of high-quality fused cast refractories and advanced engineering technology is what makes us unique.

We provide robust support for our customers at every stage of the furnace lifecycle.

Features

01Highly Trusted, High-Quality Fused cast Refractories

Refractories are critical components for glass melting furnaces, where high reliability is essential. AGC Ceramics has been providing high-quality fused cast refractories to our customers around the world for over 100 years. Notably, our High Zirconia Fused cast refractories ZB-X950 Series offers exceptional performance by minimizing defects such as stones and blisters in molten glass, earning high praise from our customers.

02Energy Saving and Greenhouse Gas Reduction for Glass Melting Furnaces

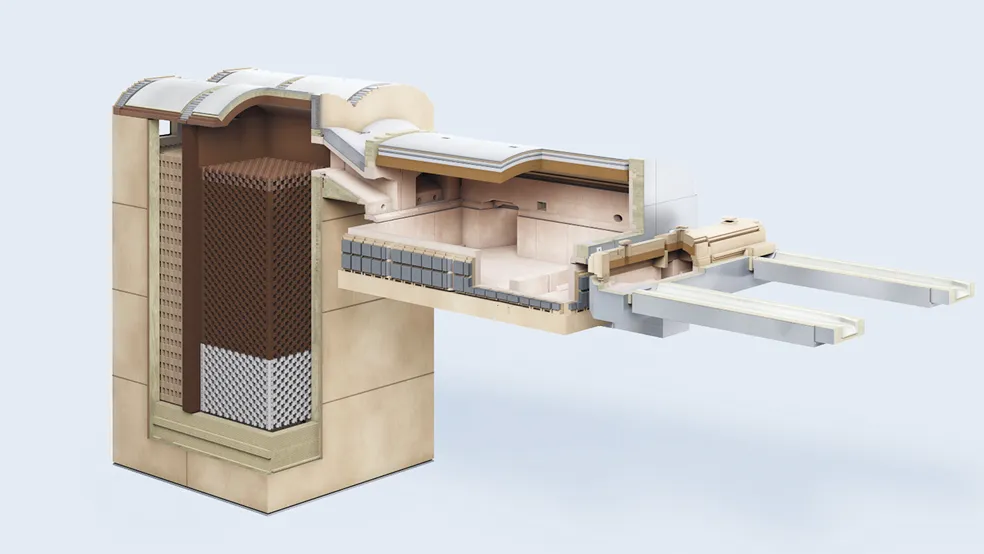

Our glass melting furnace (Ecolead Furnace) features an original high-efficiency waste heat recovery system “Hi-per Regenerator” and High Thermal Insulation Ceramics “TMT series,” offering 15–20% better fuel efficiency compared to conventional end-port type glass melting furnaces.

As further greenhouse gas reductions are required, the AGC Group continues to develop technological innovations, strongly supporting the realization of a sustainable society.

03Operation Support for Glass Melting Furnaces

Proper daily maintenance is vital for stable operation and long service life of glass melting furnaces.

AGC Ceramics not only possesses in-depth knowledge of refractory materials, but also leverages extensive operational expertise accumulated by the AGC Group. We are committed to supporting safe and secure operation environments tailored to our customers’ needs.

Refractories

Fused cast Refractories

Selected refractory raw materials are heated in an arc melting furnace at 1,900℃–2,500℃, fully melted, cast into designated molds, and slowly cooled and solidified to produce refractories. Compared to ordinary refractories, this manufacturing method produces bricks that are extremely dense and strong, composed of stable minerals, resulting in excellent corrosion and abrasion resistance.

Bonded Refractories

For glass melting furnaces, AGC Ceramics manufactures and procures bonded refractories such as basic bricks, high alumina bricks, fireclay bricks, and various special bricks.

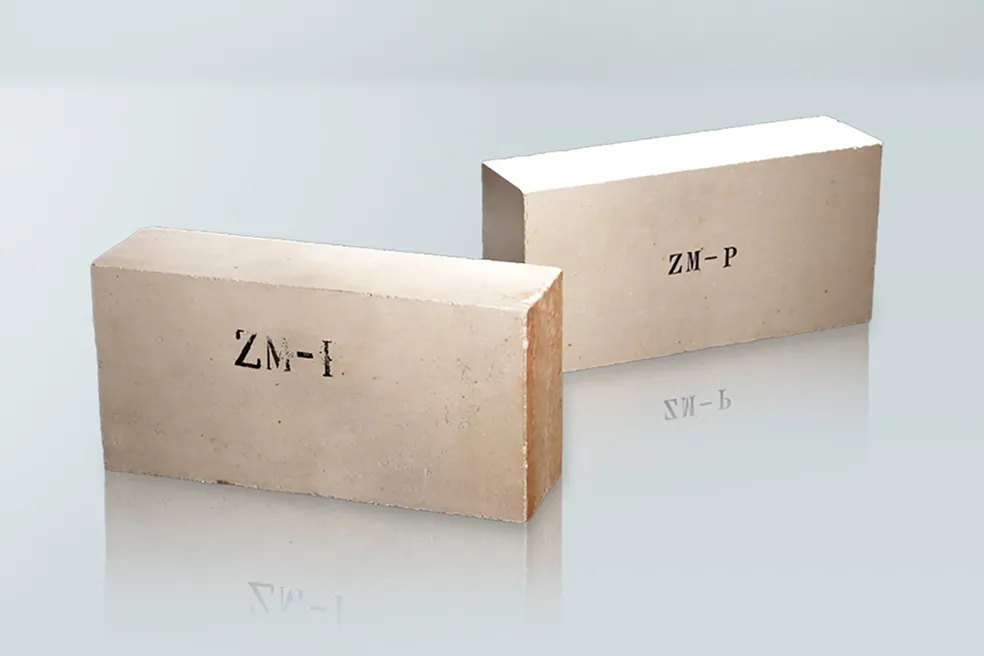

AGC Ceramics Products

ZIBO GT NEW MATERIALS GROUP CO., LTD. Products

Monolithic Refractories

In furnace construction, along with bonded bricks, mortars and monolithic refractories are essential for building robust structures. We manufacture various mortars suitable as joint materials for bricks, as well as various monolithic refractories.