Forming Method

Optimal forming technology for small-lot prototyping to mass production.

Our company utilizes accumulated forming technology and know-how to propose optimal manufacturing methods tailored to the diverse needs of our customers. In addition to general forming technologies, we possess unique proprietary technologies that enable us to produce from small-lot prototyping to mass production.

Specialized Slurry Forming Technology

Introduction

Specialized slurry forming technology achieves near-net shaping close to the final shape by converting raw materials into slurry and pouring them into molds.

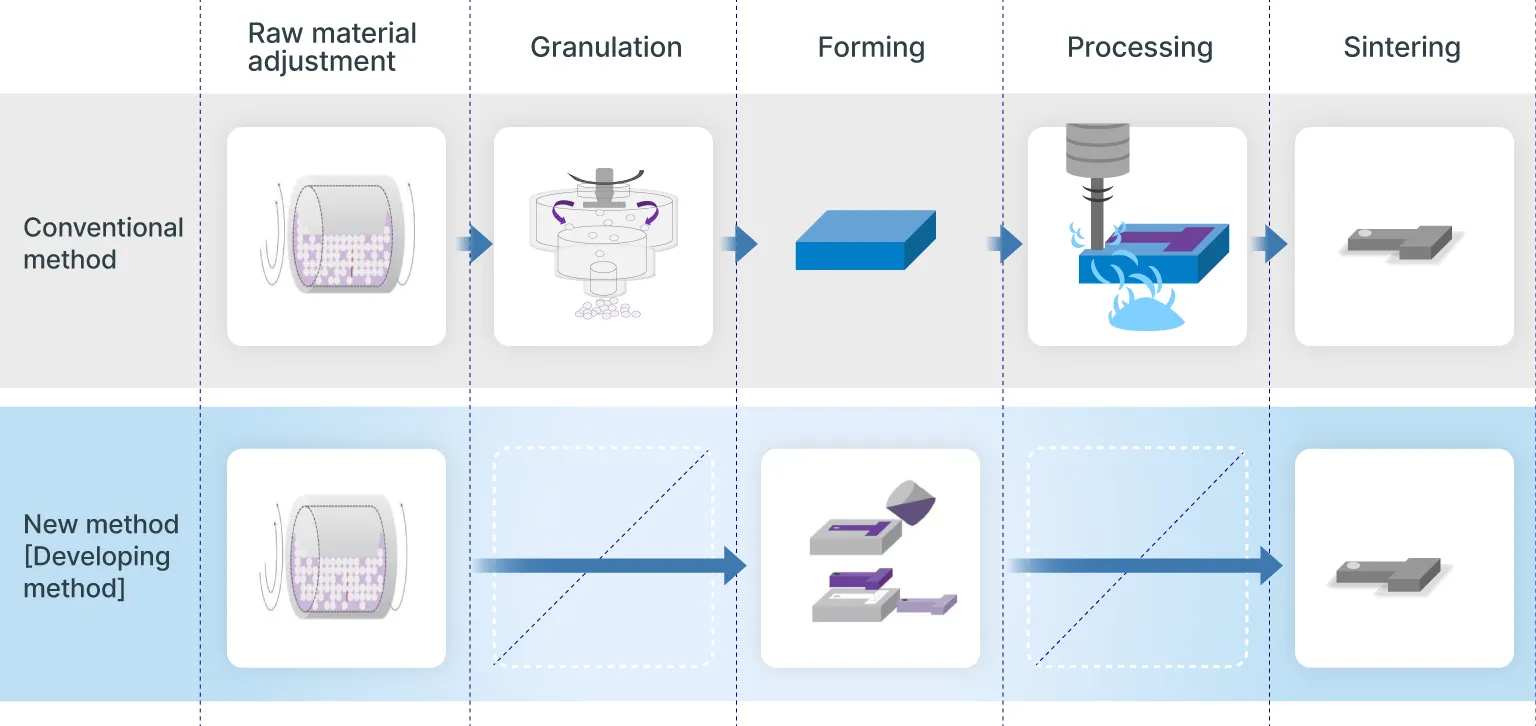

Manufacturing process

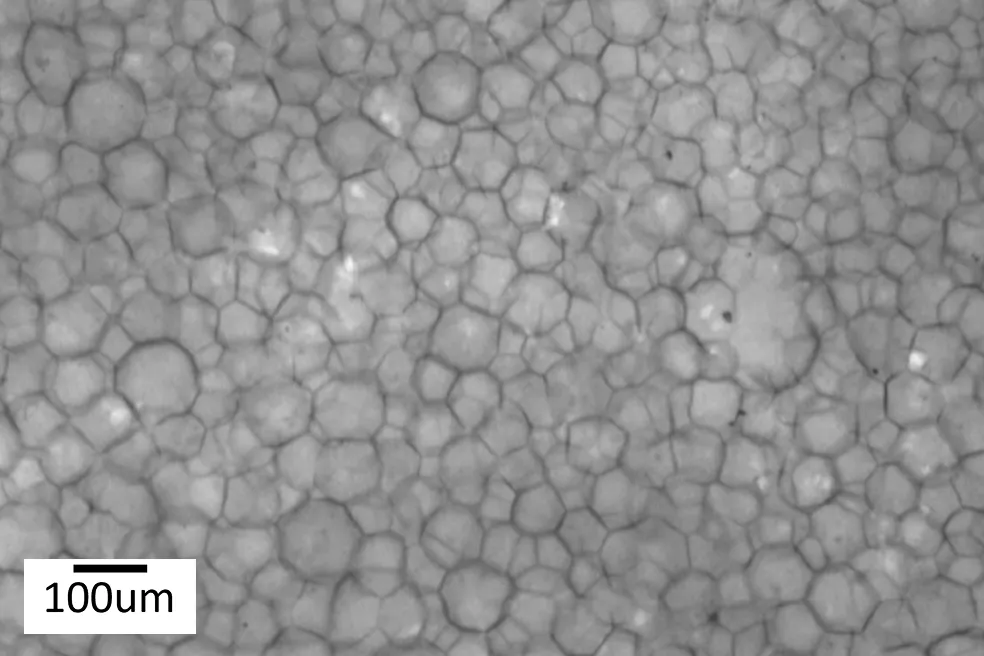

Microstructure produced by conventional methods

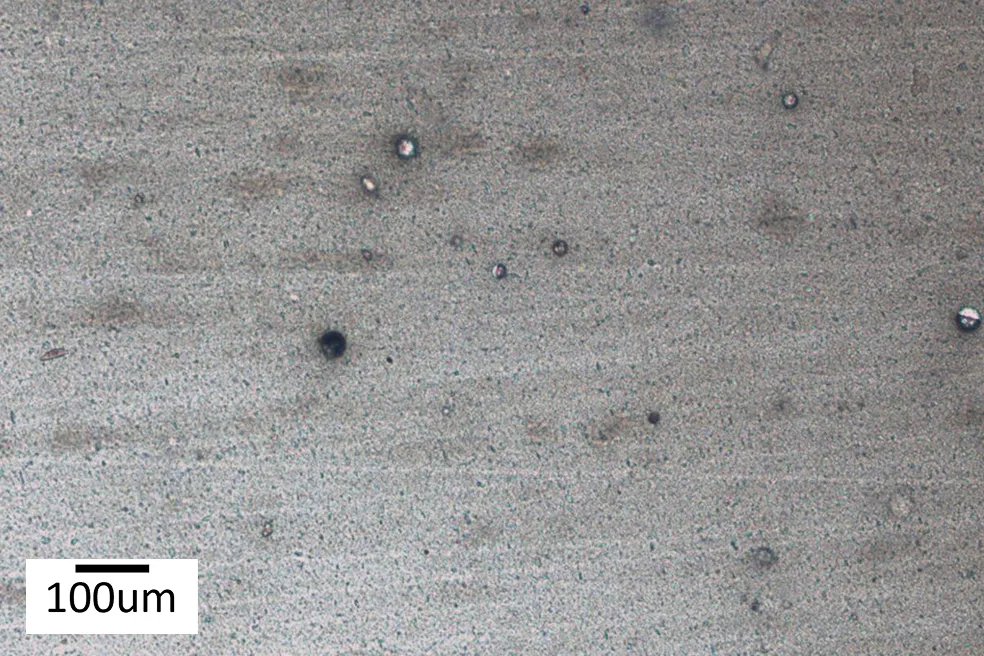

Microstructure produced by our specialized slurry forming technology

Advantages

Realization of complex shapes at reasonable cost

By converting raw materials into a specialized slurry and pouring them into molds, near-net shaping is achieved. Complex shapes at reasonable cost that were previously difficult to manufacture can now be produced.

Balancing environmental considerations and productivity

Our specialized slurry forming technology allows efficient use of raw materials, reduces processing load, and enables environmentally friendly and efficient manufacturing.

Support from small-lot prototyping to mass production

Utilizing specialized slurry forming technology, we can produce from small-lot prototyping to mass production, supporting you at every stage of development.

Applicable materials

- SiC (CERAROI™-C)

- Si3N4(CERAROI™-N)

- Cordierite (LOTEC™-M)

Other General Forming Methods

Introduction

The optimal forming method is selected according to raw material composition, product shape, production volume, etc. At this stage, the forming method is determined considering post-firing processing methods and required dimensional accuracy, and the mold is designed. The main forming methods are shown in the table below.

| Forming Method | Description | Freedom of Shape | Suitable Products |

|---|---|---|---|

| Mechanical Press | The method of placing raw material powder into a mold and forming by uniaxial pressure | ★★☆☆☆ | Simple shapes such as flat plates and cylinders, small products |

| Injection Forming | method of heating raw materials with added thermoplastic resin and filling them into a mold for forming. Large volume and shapes are also possible | ★★★★★ | Complex shapes, mass production |

| Extrusion Forming | A method of heating raw materials with added thermoplastic resin and extruding them from a mold | ★☆☆☆☆ | Long pipe-shaped products |

| CIP Forming | A method of forming by cold isostatic pressing in water using a mold or rubber mold | ★★★☆☆ | Long pipe-shaped products, plates, block shapes, large products |

| Casting Forming | A method of forming by pouring well-dispersed slurry of raw materials into a water-absorbing mold, which absorbs the moisture | ★★☆☆☆ | Flat plates, cylindrical shapes |

| Specialized Slurry Forming | Our unique method: raw materials are converted into slurry and poured into molds to achieve near-net shaping close to the final form | ★★★★★ | Complex shapes, suitable for small-volume production |

Others (High Temperature Adhesion Technology)

Introduction

It is often challenging to manufacture large and complex-shaped fine ceramic components, and considering costs, it is not realistic.

When customers are considering alternatives to metals, this issue becomes a significant obstacle to the application of fine ceramics.

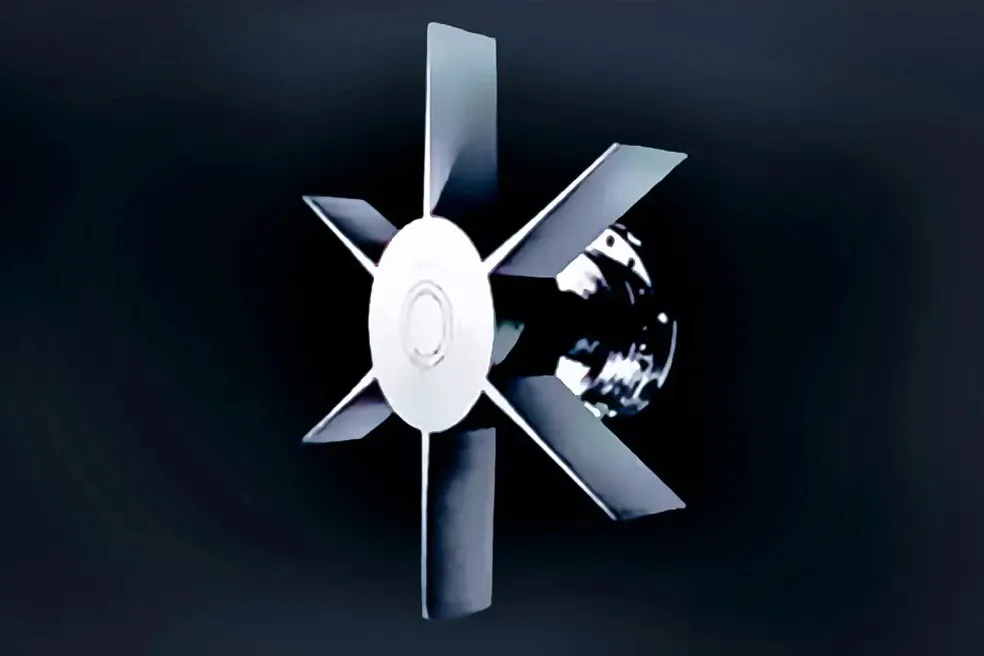

Our adhesion technology is strong enough to withstand mechanical and thermal stresses exceeding 1000℃. It is also employed in fans that blow ultra-high temperature gas at approximately 1250℃.

Advantages

Large and complex shapes are now possible

Through technology that divides and joins components, large and complex shapes that were previously difficult to achieve with conventional components can now be realized using fine ceramics.

Heat resistance exceeding 1000℃

Our unique joining technology provides high durability, enabling bonded fine ceramic components to be used in high-temperature regions exceeding 1000℃.

Reliability proven by results

Our strength lies in our proven track record of practical application, such as large and complex-shaped fine ceramic components with impeller diameters of 700 mm.

Applicable materials

- SiC (CERAROI™-C)