Glass Engineering

Comprehensive Support Technology for the Lifecycle of Glass Melting Furnaces

Through years of accumulated engineering expertise in glass melting furnaces, we achieve high-quality glass melting and high energy efficiency.

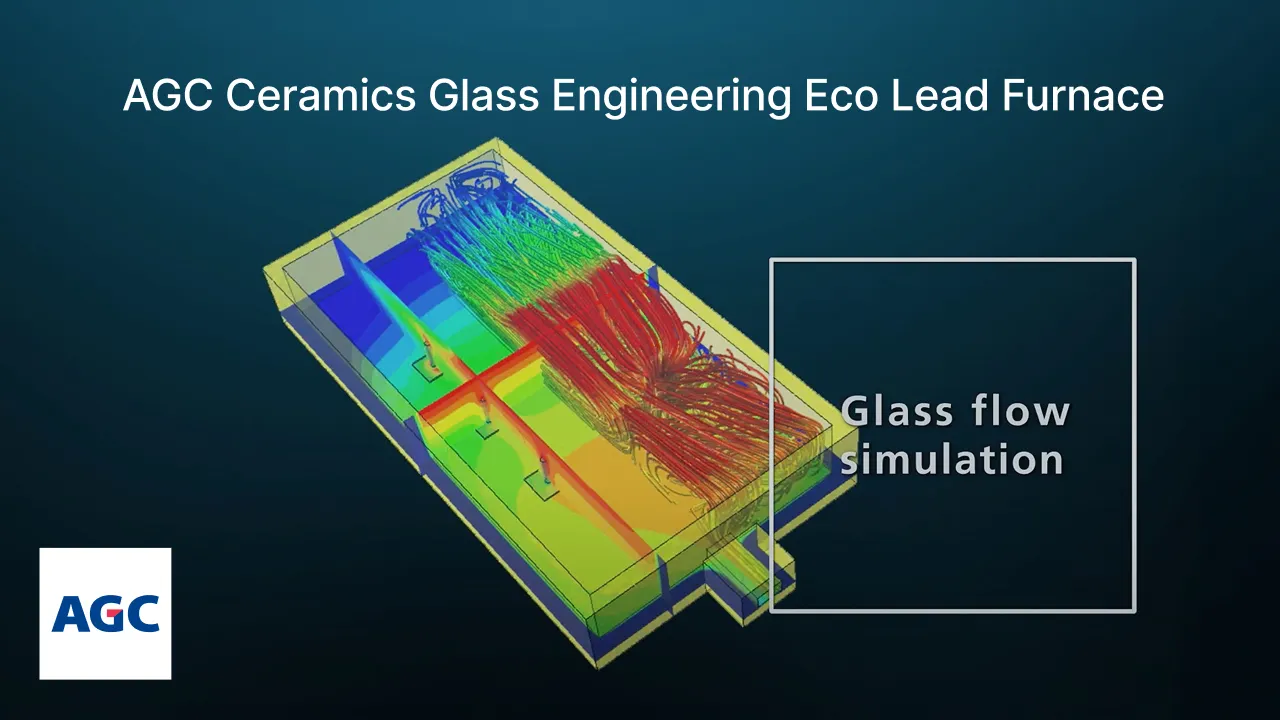

As a refractory manufacturer, we provide significant value with optimal refractory selection and placement, as well as advanced melting simulation technology.

Features

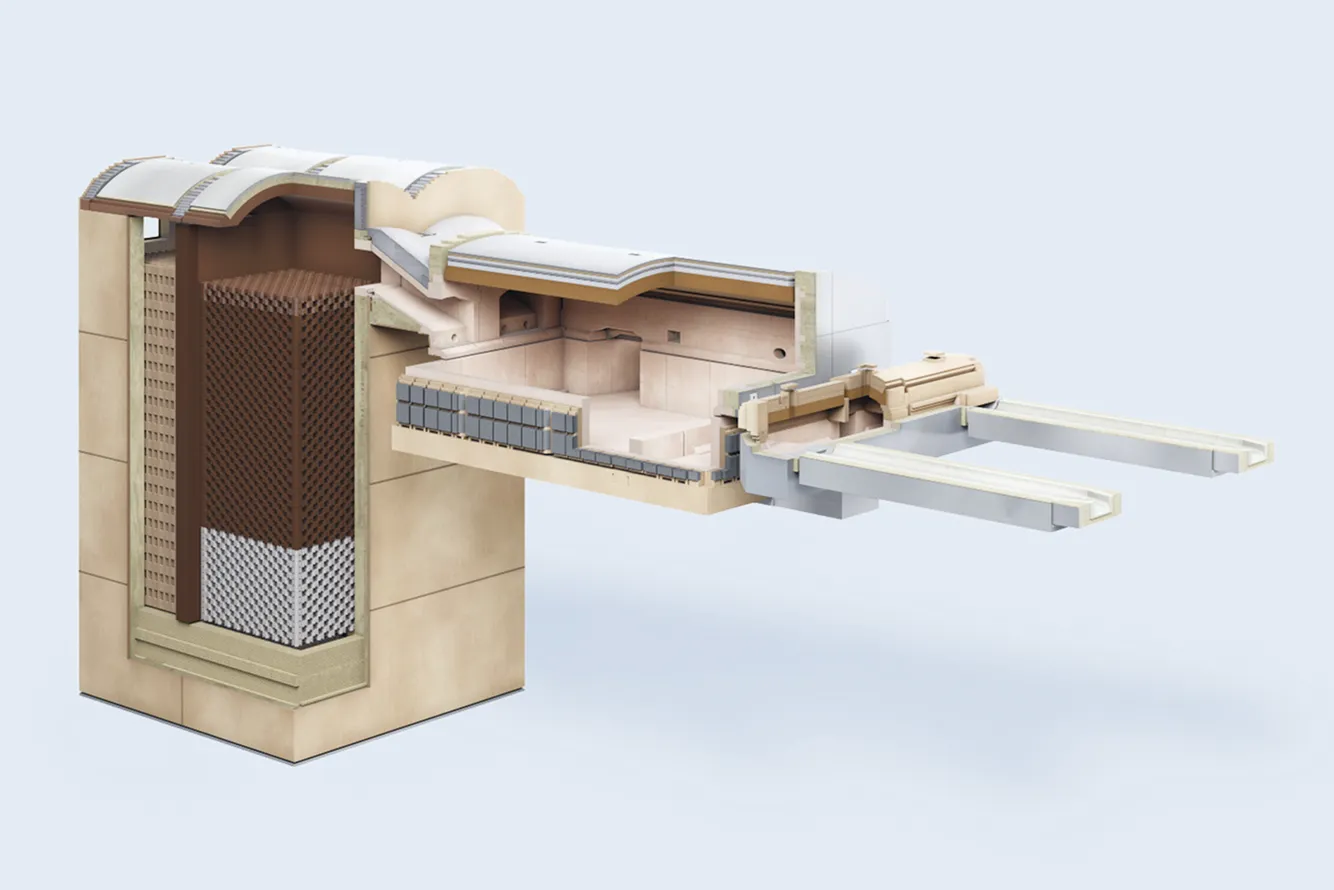

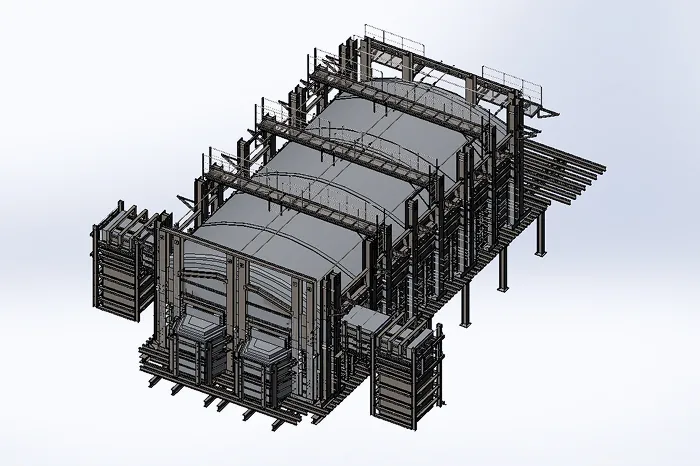

01.Glass Melting Furnace with Advanced Energy-Saving Technology (Ecolead Furnace)

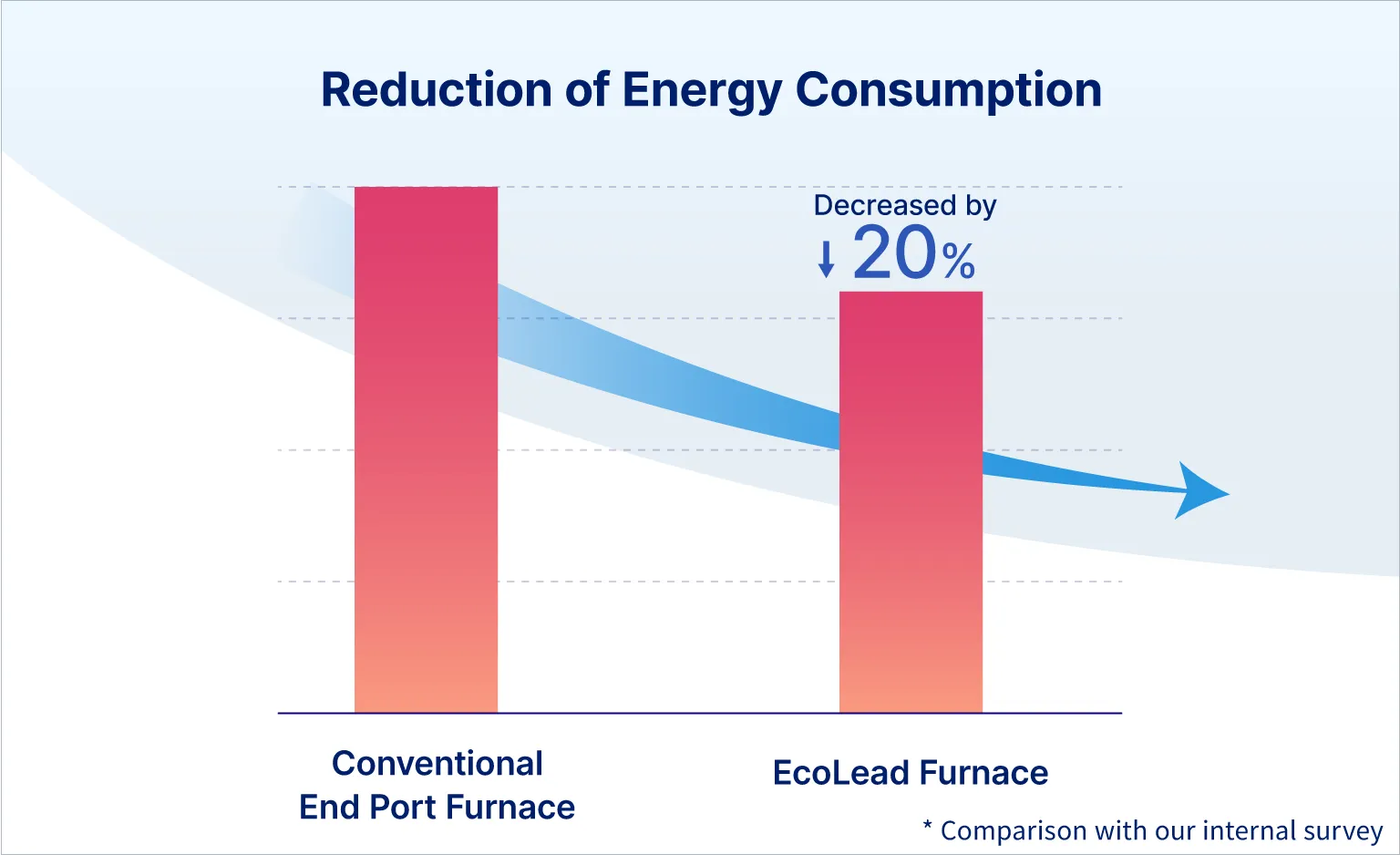

By utilizing our proprietary high-efficiency waste heat recovery system “Hi-per Regenerator” and High Thermal Insulation Ceramics “TMT series,” our furnace designs achieve up to 15–20% better fuel efficiency compared to conventional end-port type designs.

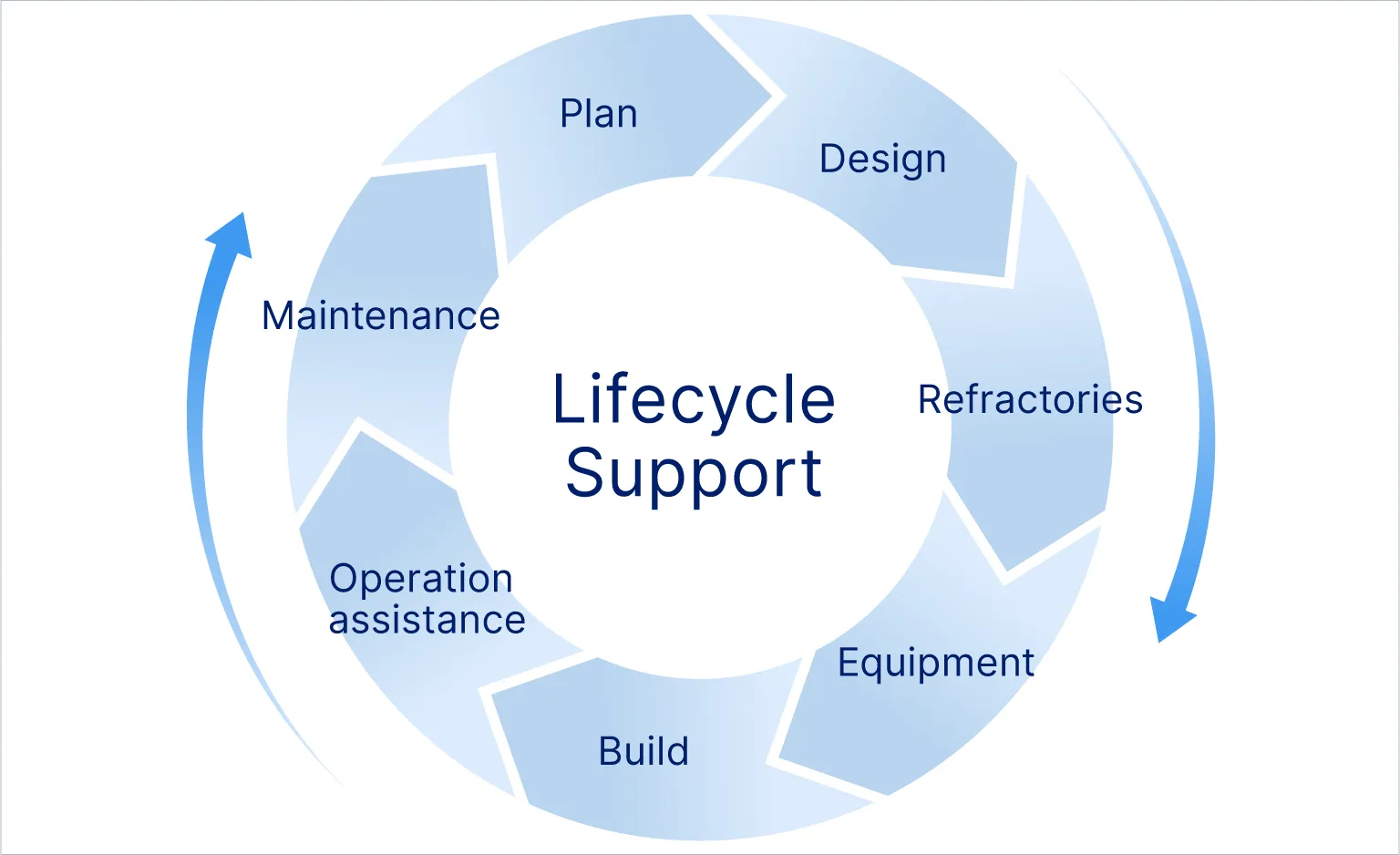

02.Supporting the Lifecycle of Glass Melting Furnaces

We offer tailored solutions for every stage of the furnace lifecycle—Design, Building, Operation Assistance, and Maintenance—meeting customer requirements at each phase.

-

step01Plan & Design

We respond flexibly to customer needs, including turnkey engineering for glass melting furnaces.

We also propose ways to minimize investment by maximizing the reuse of existing steel structures and equipment, and by working together with customers to reduce fuel costs through energy-saving technologies.

-

step02Construction

Our experienced engineers have worked on glass melting furnace construction projects worldwide, with over 150 new and renovated furnaces delivered in more than 20 countries.

-

step03Operation Support & Maintenance

Daily maintenance is crucial for long-term stable operation of glass melting furnaces.

Additionally, by leveraging digital technologies such as long-term trend analysis and remote monitoring, and the AGC Group’s extensive experience and technical capabilities, we support the long-term stable operation of our customers’ furnaces.

Technological Innovation for a Sustainable Society

To realize a sustainable society, the AGC Group is taking on future-oriented technological challenges such as increasing electrification rates and the use of hydrogen/ammonia combustion.