Dense Dry-Gunning Castable

Asahi Caster GRAM Series

- Dry Gunning Application

- Excellent Thermal Spalling Resistance

- High Corrosion Resistance

Applications: Combustion chamber walls, ceilings, boiler walls (SiC type)

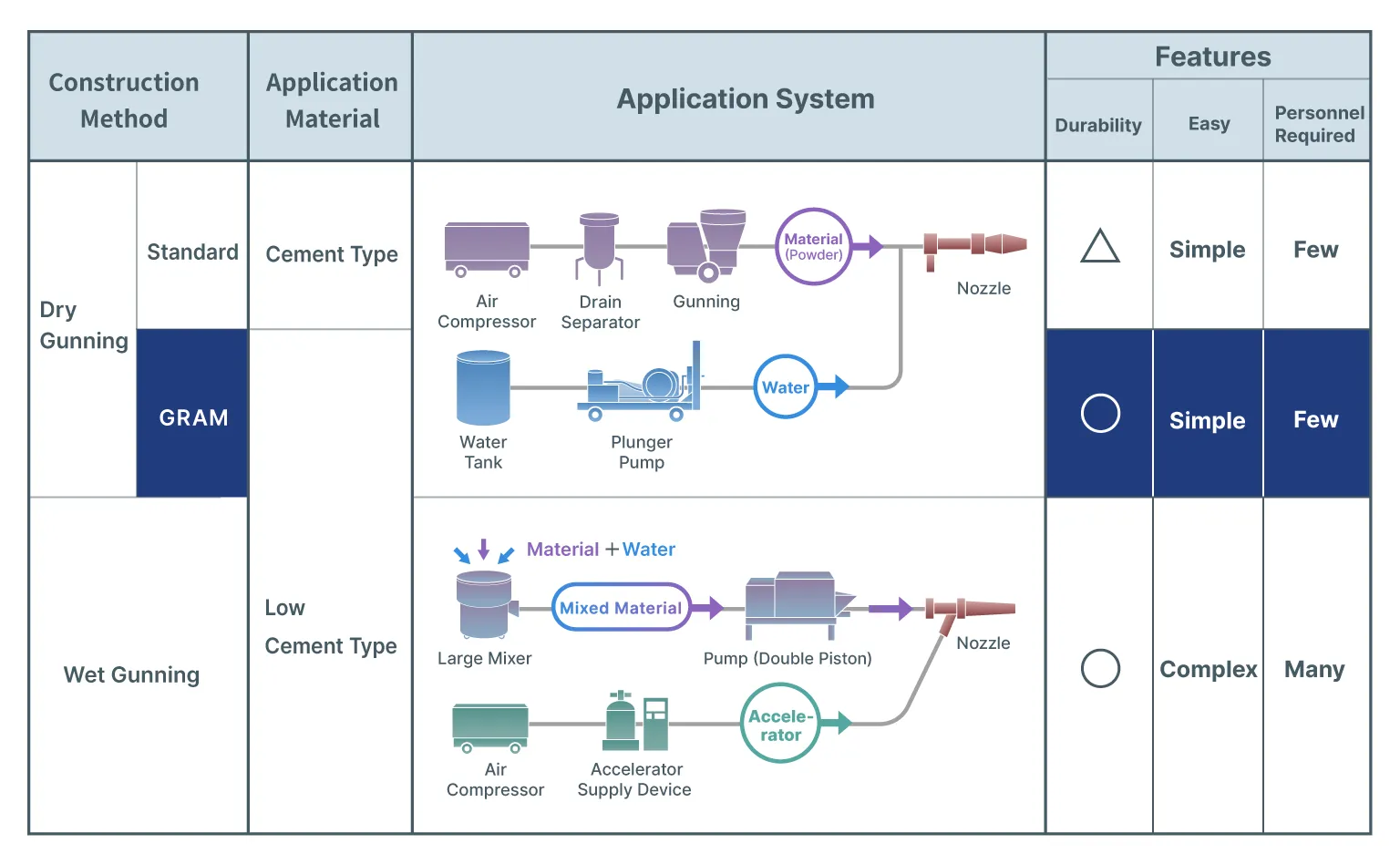

An innovative gunning monolithic refractory that combines the ease of dry gunning application with the high durability of low-cement materials.

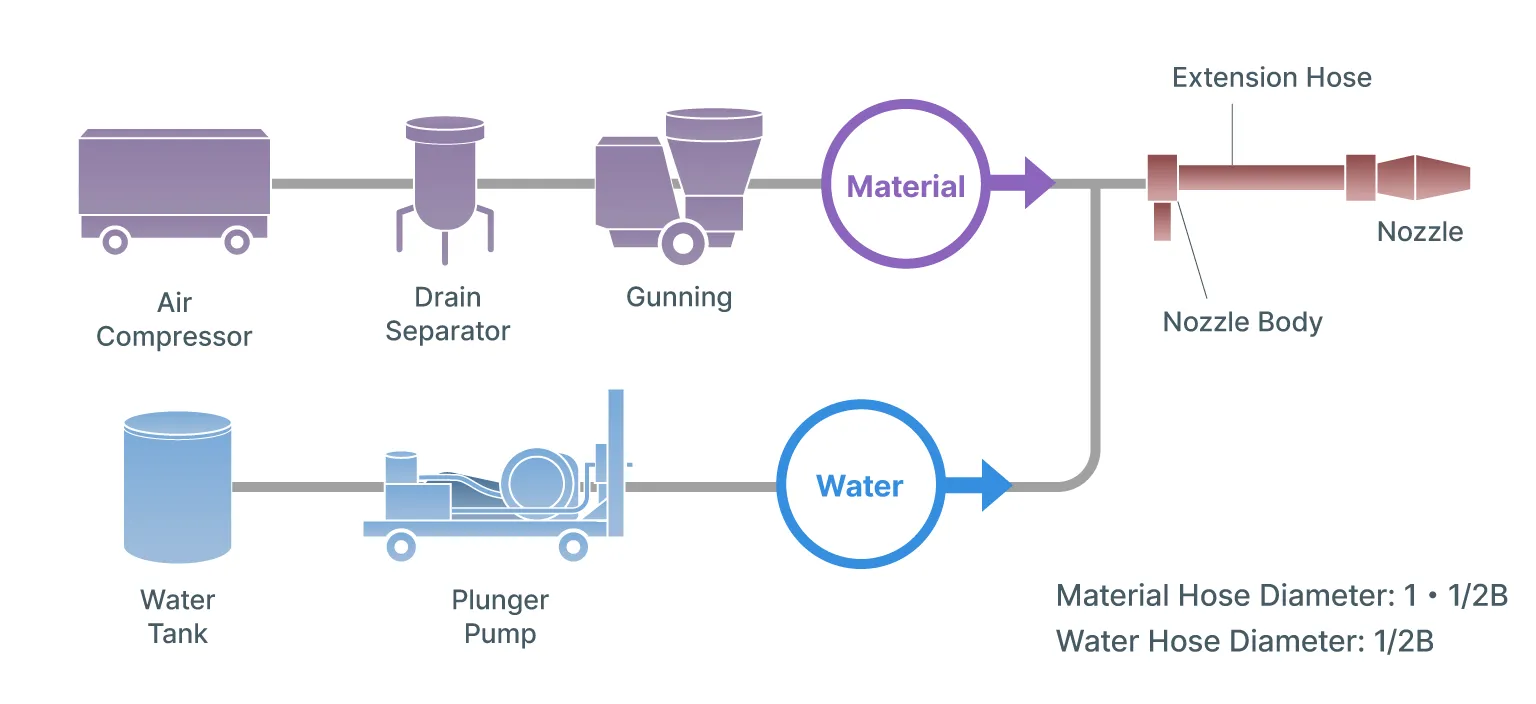

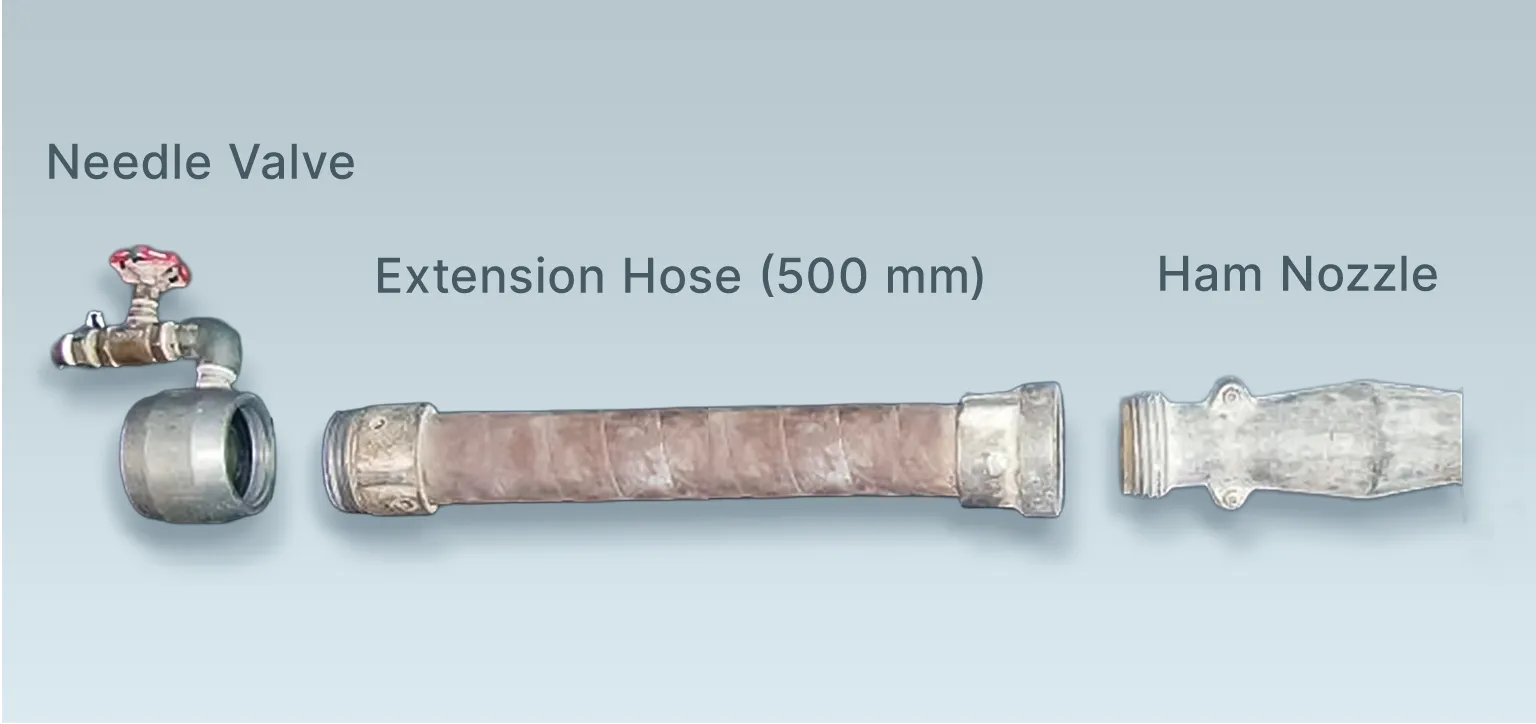

No special equipment is required; application can be done with standard gunning machines. When performing gunning installation, a needle valve and extension hose are required. Patch/trowel application is also possible.

Installation Methods

-

Dry gunning application

-

patch/trowel application

Features

01. Installable with Standard Gunning Machines

A low-cement castable that can be installed using ordinary dry-gunning machines. No special equipment is needed; standard gun machinery is sufficient.

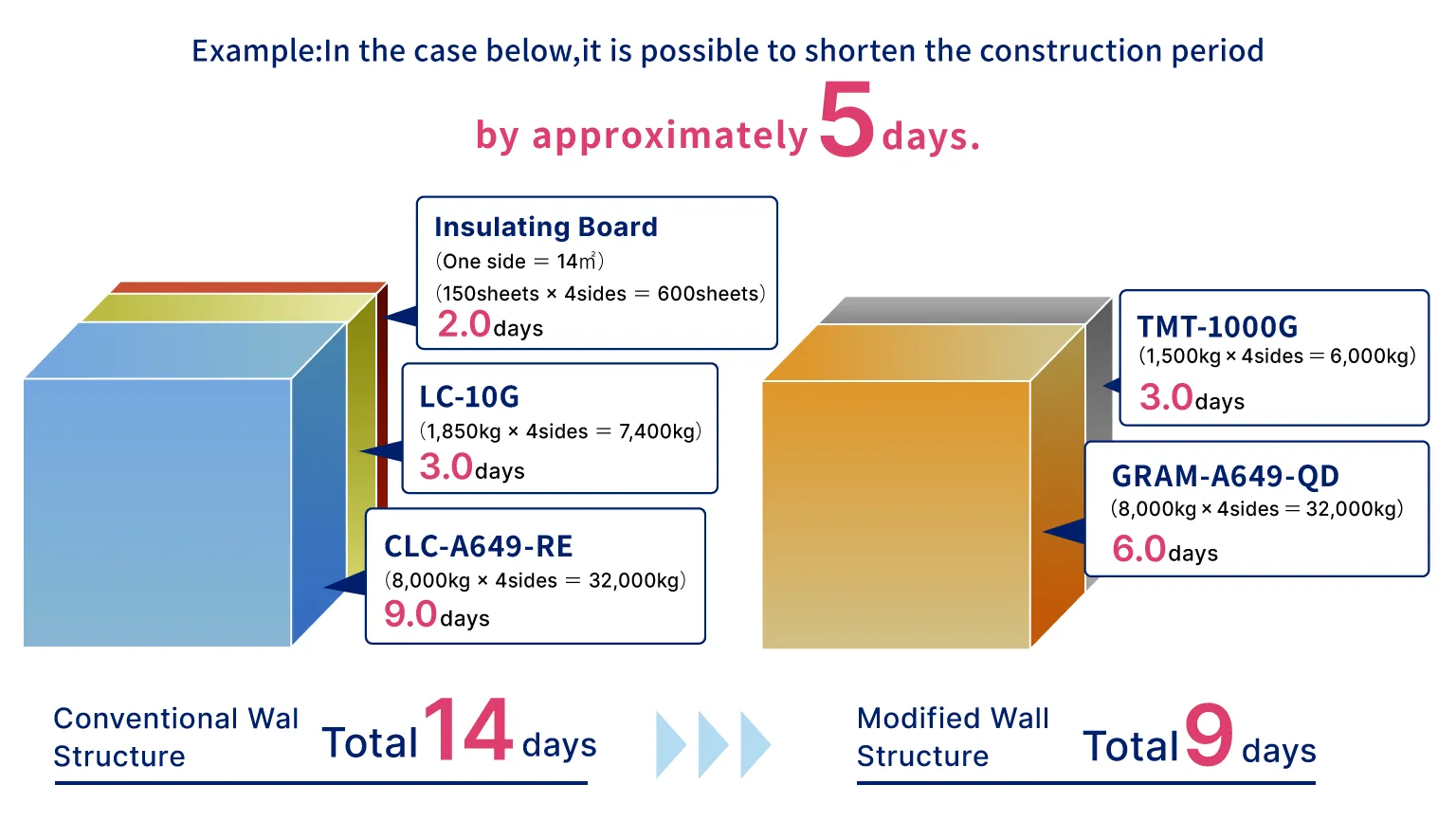

02. Shortened Construction Time

Gunning application does not require formwork installation or removal, contributing to reduced construction time.

03. Shortened Drying Time

Many GRAM series products are available in QD series, maximizing the benefit of shortened drying times for faster project completion.

04. Patch/Trowel Application Also Possible

GRAM series can be applied via patch/trowel installation, making it suitable for partial repairs as well.

Installation Notes

No special equipment required; can be installed with standard gunning machines.

Please refer to the instructional video for installation methods.

Equipment Arrangement

Nozzle Details

Data

Merit 1: Shortened Construction Time

Contributes to shorter construction time through all dry gunning application methods.

Merit 2: Reduced Drying Time & Lower Risk of Explosion

The QD type enables rapid heating, which shortens drying time and reduces the risk of explosion.