Sillimanite

(G-AS-60, 60Z, 60J)

- Anti-spalling Resistance

- High Corrosion Resistance

Made mainly from carefully selected sillimanite (Al₂O₃–SiO₂), these high corrosion resistance bonded refractories are manufactured under optimal conditions for excellent anti-spalling properties. Various shapes can be produced by press forming or casting, mainly used for feeder covers, burner blocks, and sidewalls of glass melting furnaces.

Features

01. Anti-spalling Resistance

Excellent anti-spalling properties make them suitable for superstructures with large temperature variations.

02. High Corrosion Resistance

They offer high resistance against glass vapor, maintaining stable performance in severe conditions such as burner blocks and superstructures.

Product Lineup

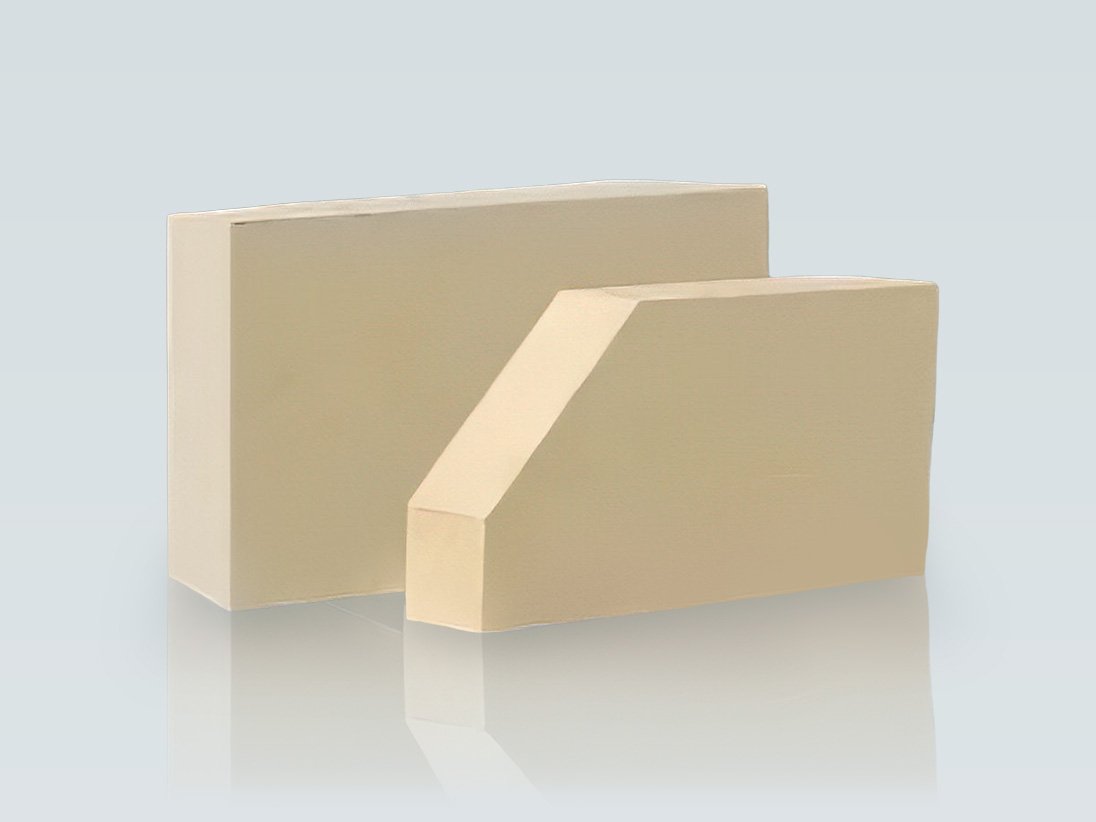

G-AS-60

Press-formed sillimanite bricks with excellent anti-spalling properties.

G-AS-60Z

Casting-formed sillimanite bricks suitable for large shapes.

G-AS-60J

Casting-formed sillimanite bricks suitable for special shapes.

Chemical composition

| G-AS-60 | G-AS-60J | G-AS-60Z | |

|---|---|---|---|

| SiO2 | 31% | 33% | 33% |

| Al2O3 | 68% | 65% | 65% |

| Fe2O3 | 0.6% | 0.6% | 0.5% |

The quality data provided here are reference values and not guaranteed values. Quality assurance for your order will be determined separately through discussion. Please note that the listed quality data may be changed without prior notice.