High Thermal Insulation Ceramics

Asahi Caster TMT Series

- High Insulation

- Long-Term Insulation Performance

- Reduction of Radiant Heat

A monolithic refractory that contributes to energy savings by dramatically enhancing the insulation function.

By blending our proprietary special raw materials, this castable offers both high heat resistance and high insulation, usable at temperatures up to 1700℃.

We provide optimal proposals tailored to your equipment and operational needs, contributing to energy savings and environmental improvement for various industrial furnaces.

Installation Methods

-

Casting (Vibration)

-

Dry-Gunning Application

-

Troweling

-

Board Mounting

Features

01. Reduction of Radiant Heat

With insulation performance equivalent to ceramic fiber, it contributes to energy savings in various industrial furnaces. Achieves advanced energy-saving performance without containing any refractory ceramic fiber (RCF).

02. High Heat Resistance

Products are available for use in high temperature zones up to 1700°C.

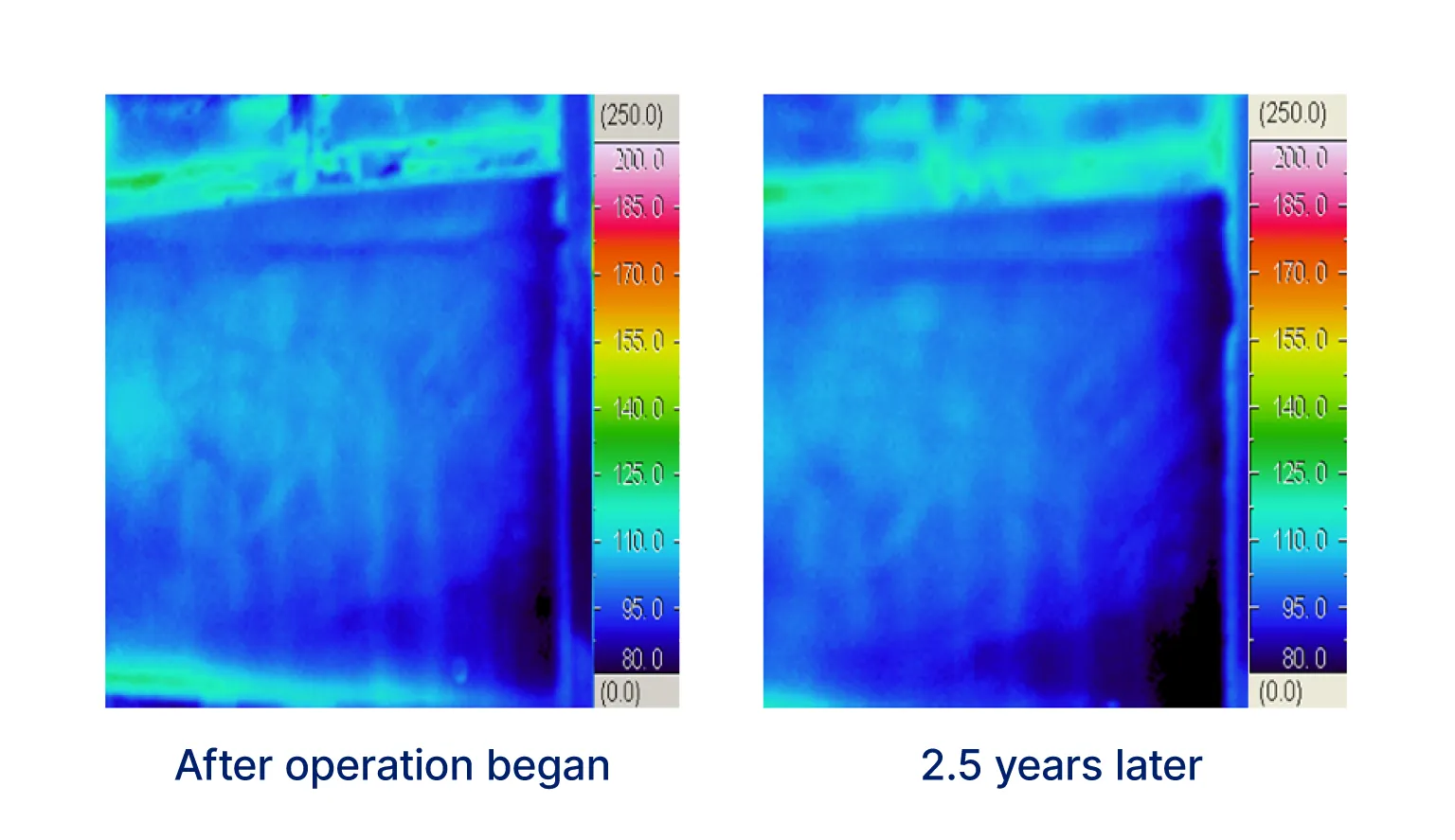

03. Long-Term Insulation Performance

Delivers long-term insulation performance that was not possible with ceramic fiber.

Long-Term Insulation Stability (Measured Data from Actual Furnace Using Thermotracer)

The diagram shows the surface temperature of Asahi Caster TMT Series represented by color.

The blue color, indicating low temperature, is maintained over long periods.

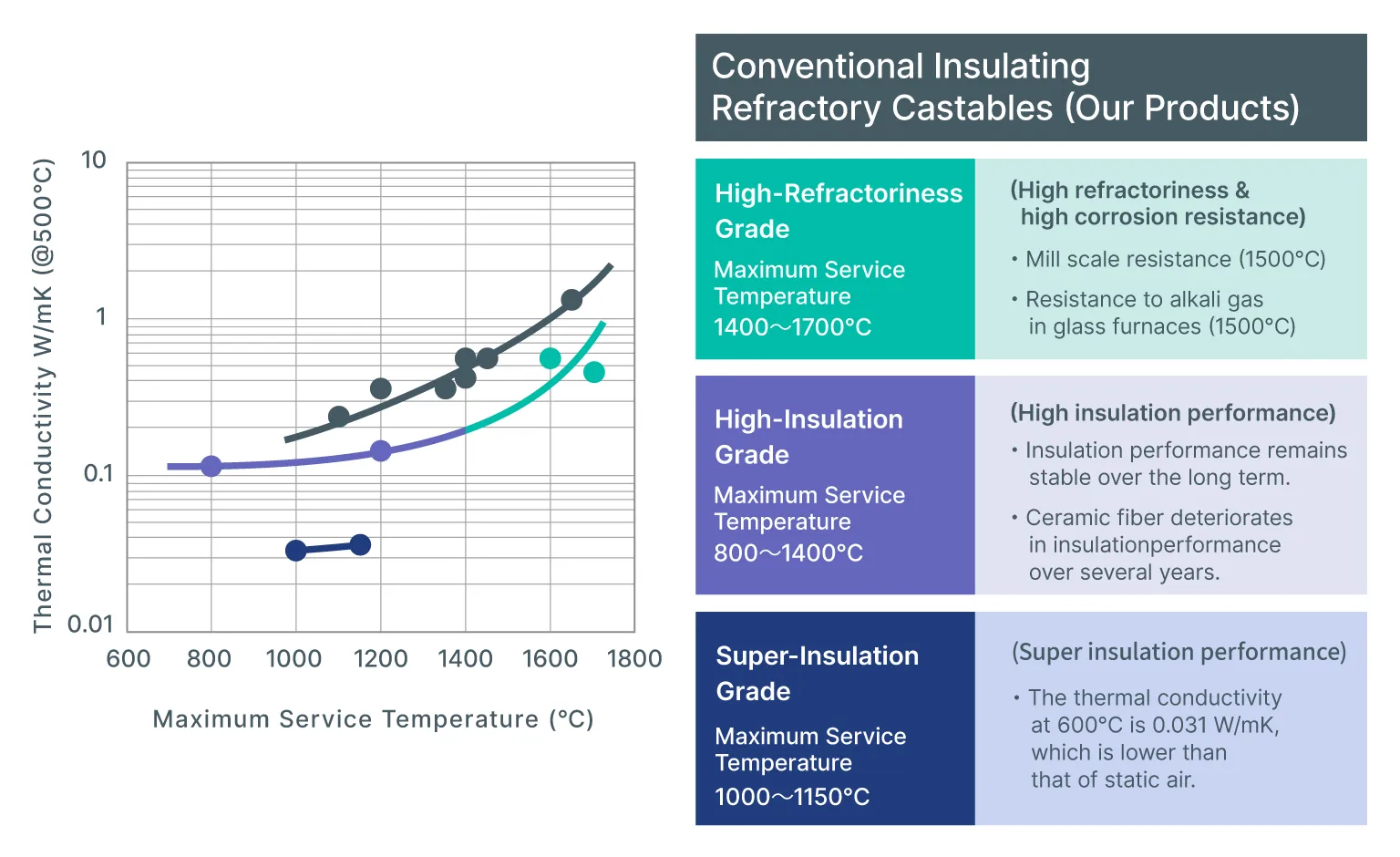

Data

Compared to conventional insulating monolithic refractory products, “TMT” offers significantly improved insulation performance.

「TMT」“TMT” products are available in three grades.

“TMT” products include both monolithic refractory products and board-type products (ultra-insulation grade).

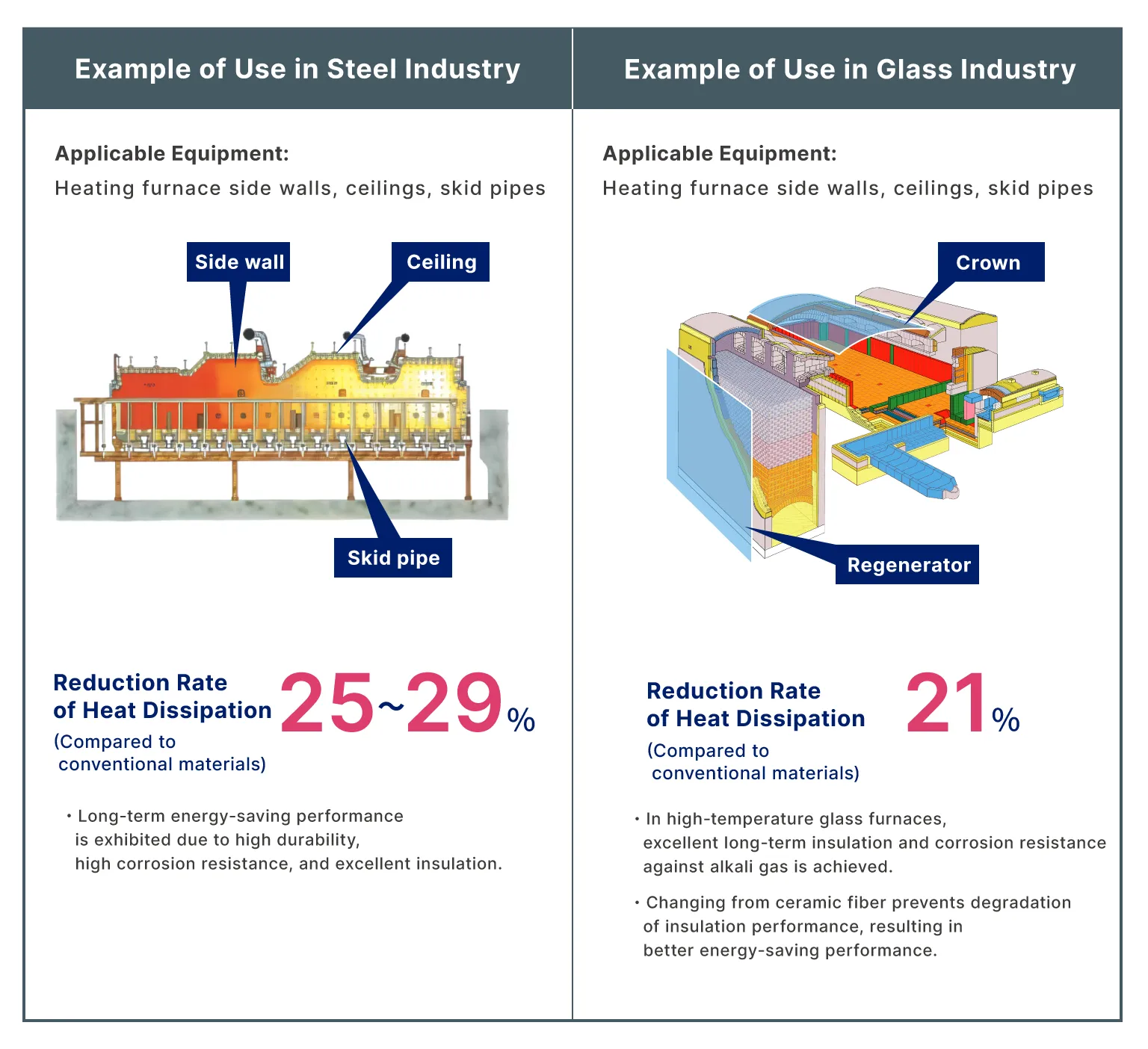

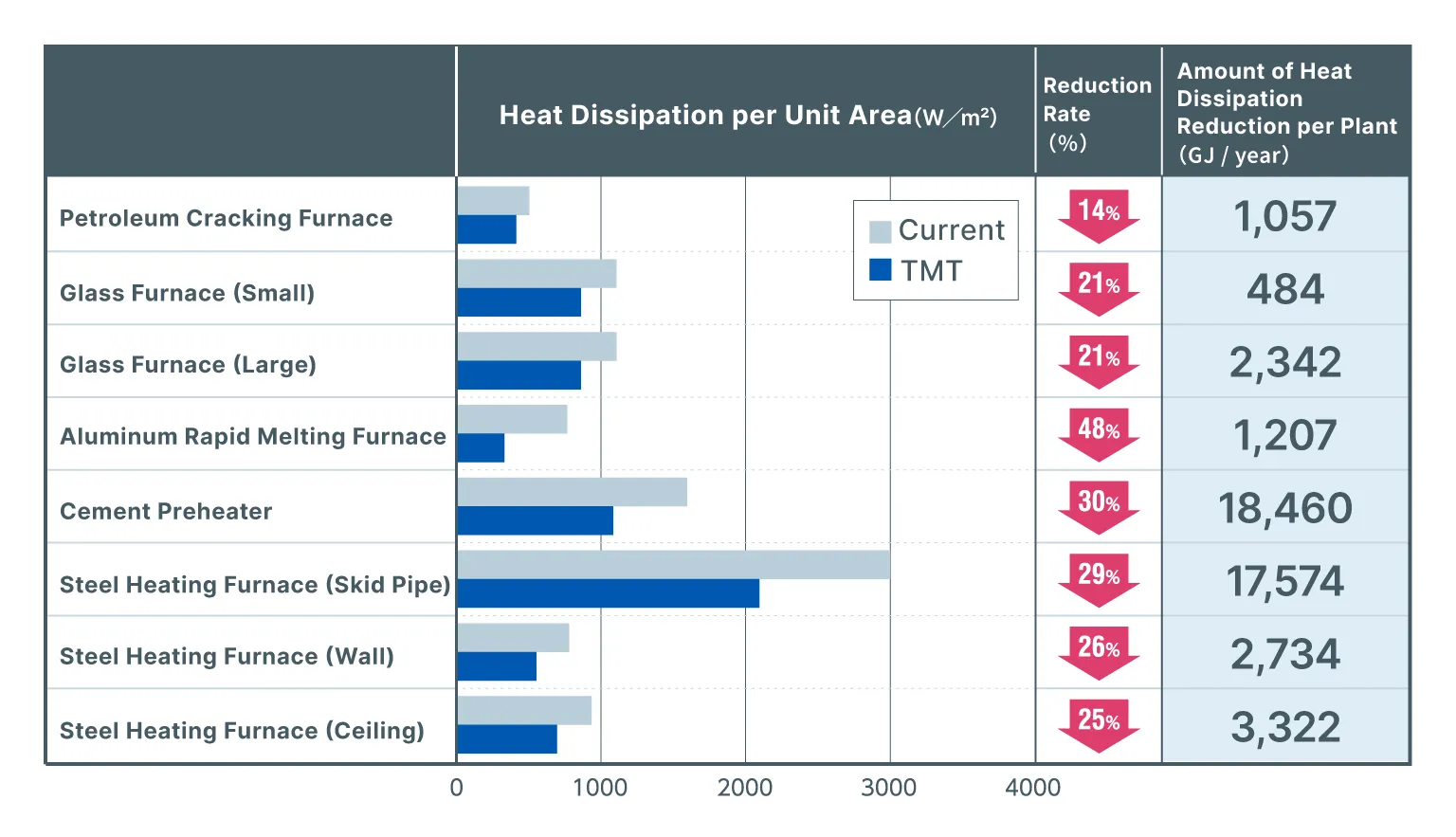

Energy Saving Performance (Estimates for Various Industrial Furnaces)

1. Radiant heat per unit area was calculated using steady-state heat conduction heat transfer calculations.

2. Annual operating hours were set uniformly at 23h/day × 365 days = 8,395h/year, considering maintenance periods.

3. The reduction in radiant heat for steel reheating furnaces (skid pipes) was calculated based on cooling water temperature.

4. The above are estimates for typical plants.

Case Studies

Implementation examples of “Asahi Caster TMT Series”.