High Zirconia Fused Cast Refractory

ZB-X950 Series

- Anti-Contamination

- High Corrosion Resistance

- High Electrical Resistivity

Developed using our advanced fused cast refractory manufacturing technology, the ZB-X950 Series is a super-premium fused cast refractory with exceptional properties.

It is highly resistant to the formation of stones and blisters in molten glass, making it ideal for contact areas in special glass melting furnaces requiring high quality.

It has been highly evaluated and proven in applications for specialty glass melting furnaces such as boro-silicate glass, glass ceramics, non-alkali glass, and alumino-silicate glass.

Features

01. Extremely High Corrosion Resistance

Using selected zirconia raw materials and optimal production conditions, we produce very dense fused cast refractories with zirconia content over 88%. They deliver outstanding corrosion resistance for direct contact with specialty molten glass, especially in areas where high corrosion resistance is required.

02. Excellent Anti-contamination

Strict quality control and high-purity zirconia raw materials ensure that defects such as impurities and blisters are unlikely to form in molten glass. This gives peace of mind for high-grade specialty glass manufacturing.

03. High Electrical Resistivity

Our proprietary formulation achieves high electrical resistivity, making these high zirconia fused cast refractories suitable for electrode blocks in all-electric glass melting furnaces.

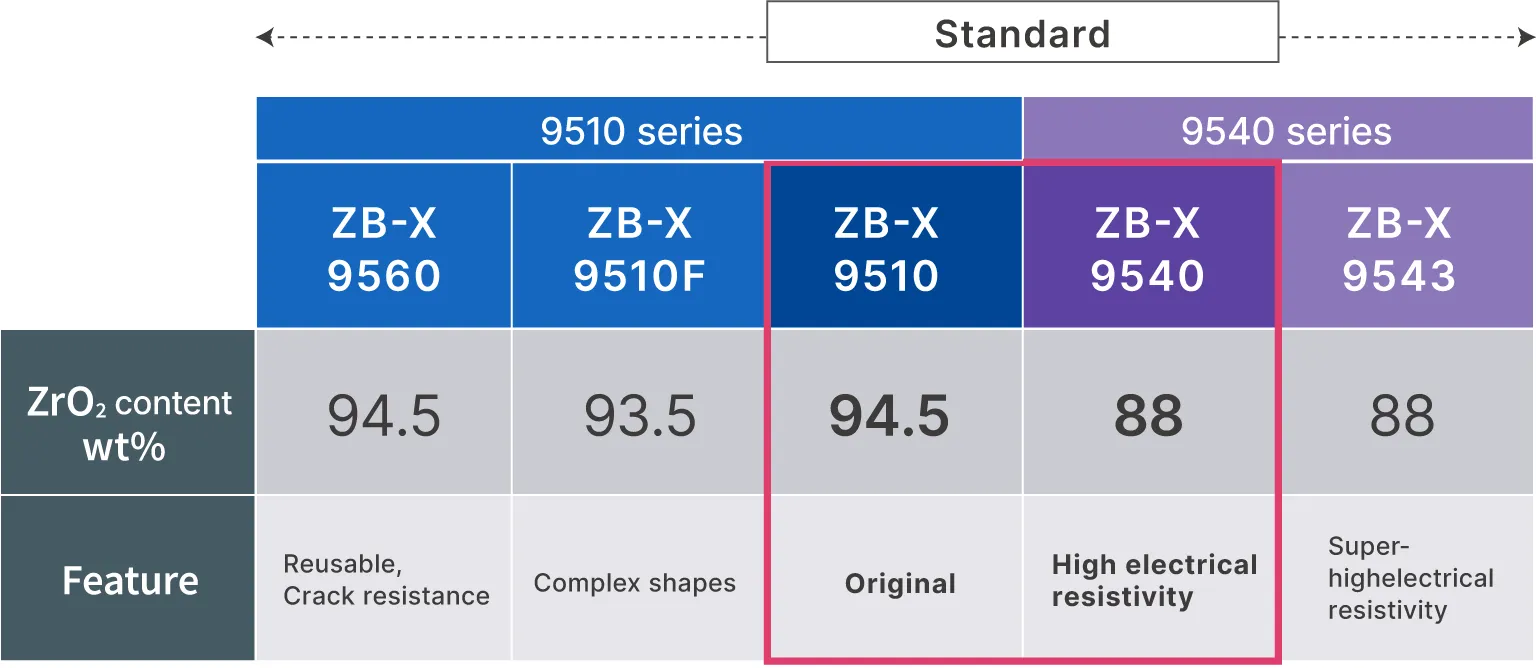

ZB-X950 Series Product Lineup

ZB-X9510

Contains 94.5% zirconia. Offers extremely high corrosion resistance and minimizes defects such as stones and blisters.

ZB-X9510F

Contains 93.5% zirconia. Optimized composition for special shapes.

ZB-X9560

Contains 94.5% zirconia, improved volume stability under temperature fluctuations, and shows excellent corrosion and anti-contamination properties.

ZB-X9540

Contains 88% zirconia, has high electrical resistivity, outstanding corrosion and anti-contamination properties, suitable for electrode blocks in specialty glass electric melting furnaces.

ZB-X9543

Contains 88% zirconia, very high electrical resistivity at high temperatures, excellent corrosion and anti-contamination properties, suitable for electrode blocks in specialty glass electric melting furnaces.

Chemical composition

| ZB-X9510 | ZB-X9510F | ZB-X9560 | ZB-X9540 | ZB-X9543 | |

|---|---|---|---|---|---|

| ZrO2 | 94.5% | 93.5% | 94.5% | 88% | 88% |

| Al2O3 | 0.7% | 0.7% | 0.6% | 1.3% | 0.4% |

| SiO2 | 4.1% | 5.1% | 4.3% | 9.4% | 10.4% |

| Na2O | 0.4% | 0.3% | ‐ | 0.02% | 0.02% |

The quality data provided here are reference values and not guaranteed values. Quality assurance for your order will be determined separately through discussion. Please note that the listed quality data may be changed without prior notice.

Casting Type

| Mark | Name | Casting Type Description |

|---|---|---|

VF |

Void Free |

After casting and cooling/solidification, the casting void portion is cut off, resulting in a product without voids. |