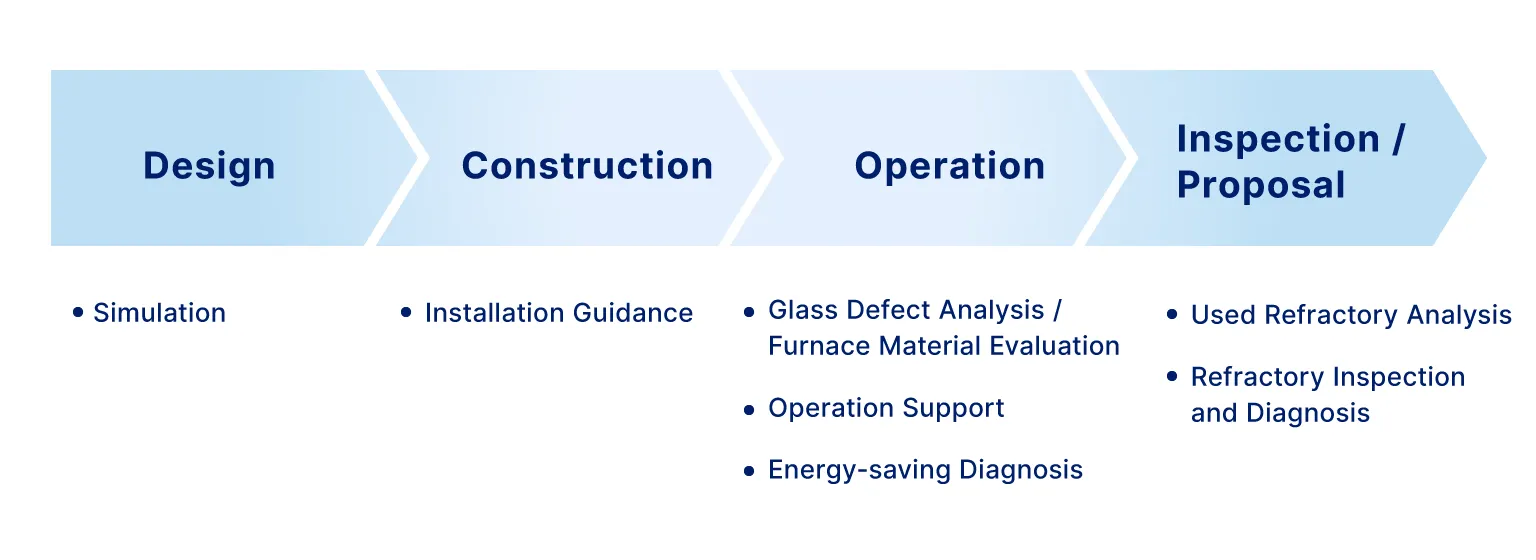

Services

Supporting the Lifecycle of Customer Equipment with Reliability and Satisfaction

We provide not only products but also services throughout the entire lifecycle of customer equipment, responding to various challenges and needs.

Features

01.Lifecycle Support

We leverage our extensive knowledge and expertise accumulated over many years to support stable operation of customer equipment.

02.Value-added Proposals

We offer various services that contribute to energy savings and labor-saving operations.

03.Utilization of Digital Technology

We harness data and digital technologies to provide new value.

Service Details

Service

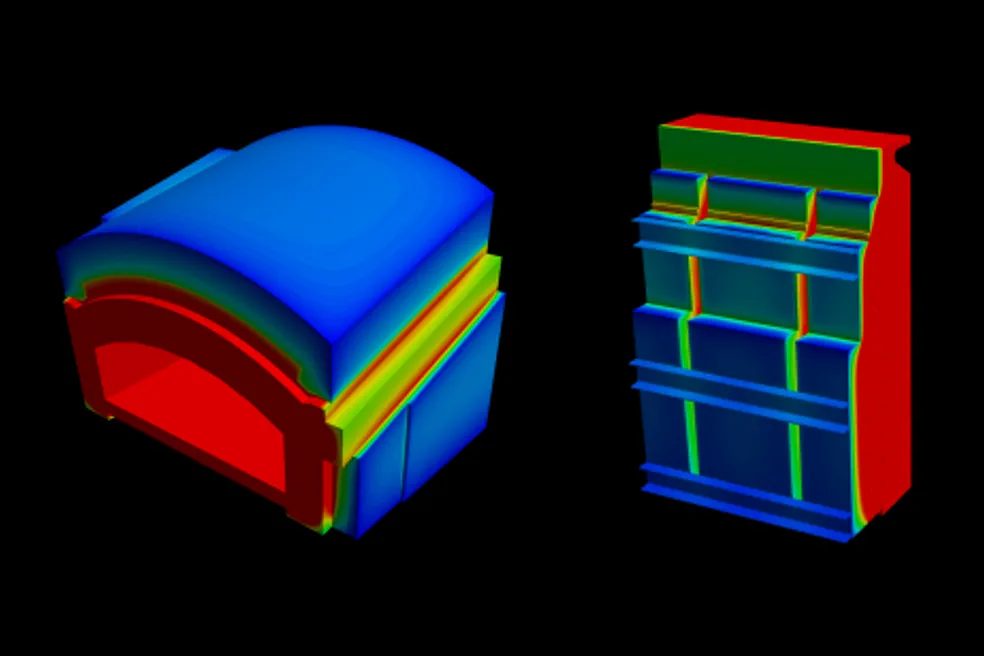

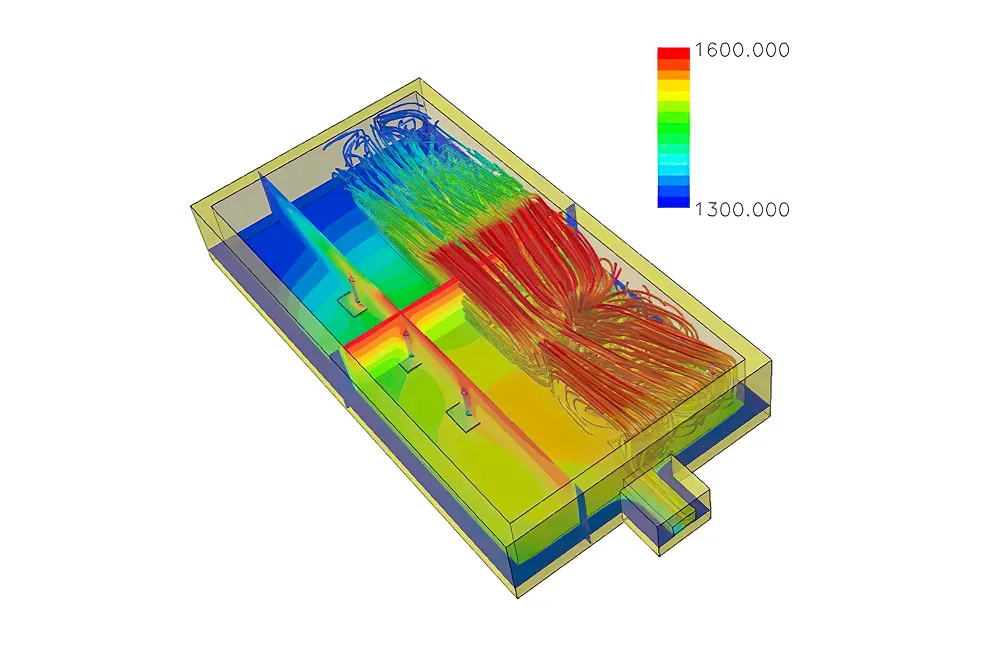

01.Simulation

- Glass

Utilizing thermal stress and fluid simulation technology developed by the AGC Group, we reproduce phenomena inside plants.

We quantitatively evaluate the effects and risks of new designs in advance, supporting energy saving and stable operation.

02.Installation Guidance

- Incinerator

- Aluminum

- Cement

Our staff visit customer sites directly to provide detailed explanations on installation methods, ensuring that the product’s original quality and performance are fully realized.

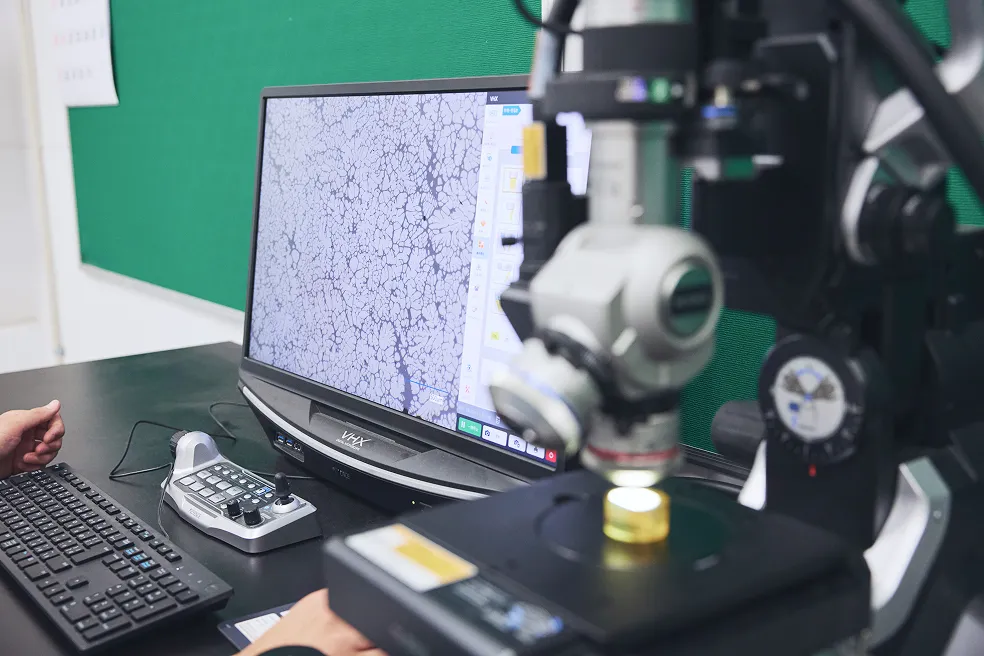

03.Glass Defect Analysis / Furnace Material Evaluation

- Glass

Applying our ceramics development and analysis technologies, we investigate and propose improvements for glass defects through chemical analysis, crystal structure analysis, and microstructure observation.

Moreover, we evaluate furnace materials under conditions close to actual operation, proposing optimal solutions.

04.Operation Support

- Glass

Based on the experience and technical strength cultivated over more than 100 years, we offer solutions for a wide range of situations, from daily maintenance to emergency troubleshooting.

05.Energy-saving Diagnosis

- Glass

- Incinerator

- Aluminum

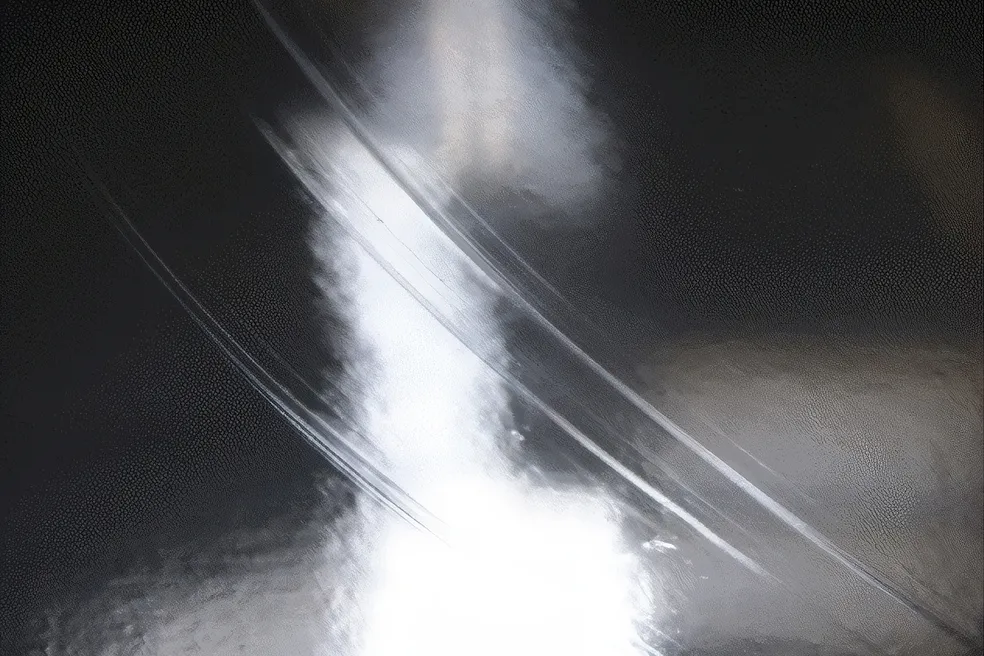

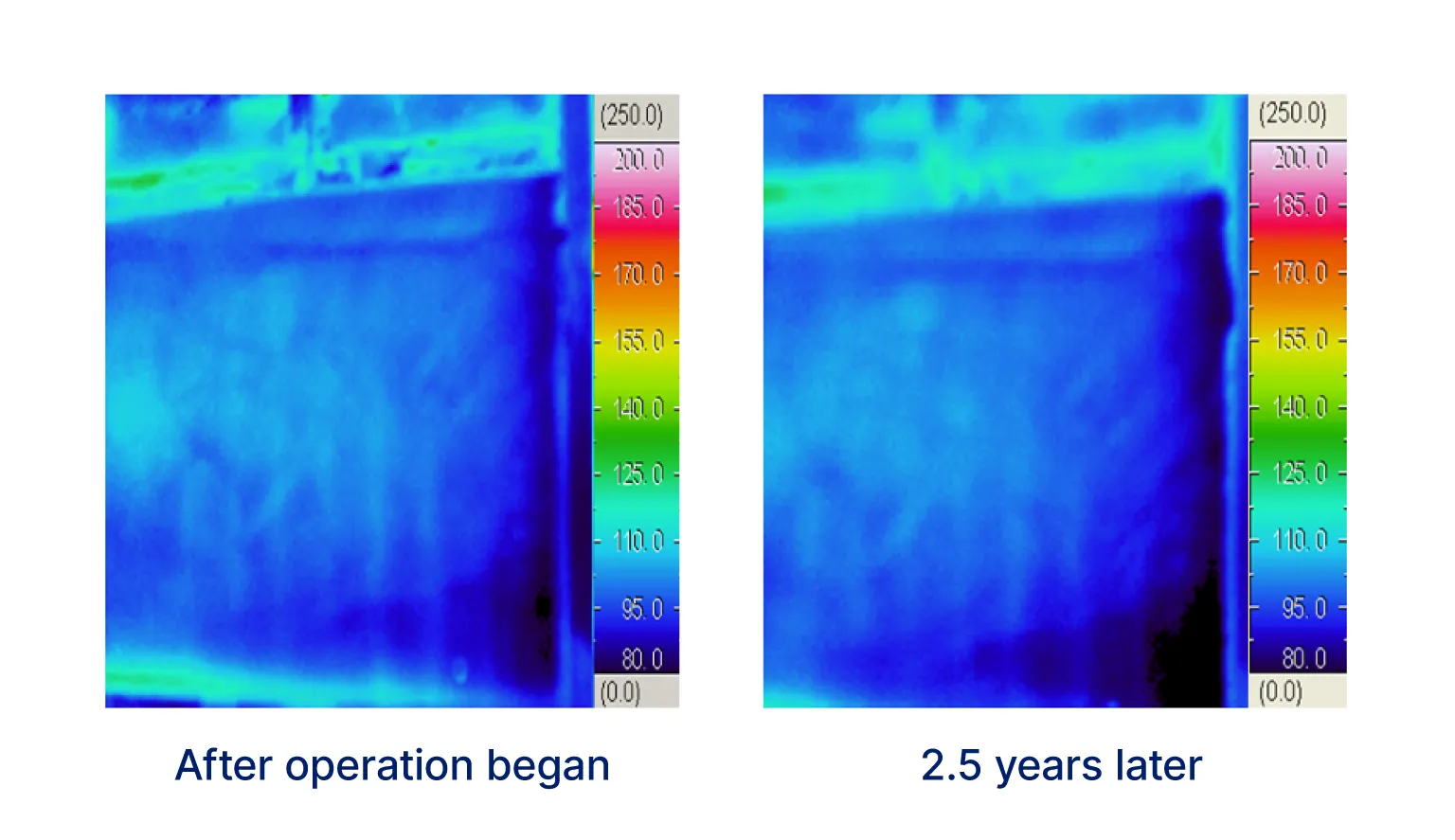

Using a thermoviewer, we measure the temperature distribution on the outside of equipment to verify the reduction in radiant heat and energy-saving effects achieved by our refractories.

We investigate and report whether the proposed fuel savings have been realized, and provide further energy-saving proposals as needed.

Through this service, we visualize reductions in environmental impact and lifecycle costs, supporting sustainable operation.

06.Used Refractory Analysis

- Glass

- Incinerator

- Aluminum

- Cement

We analyze used refractories generated during repair work or cold repair in plants and glass melting furnaces to identify damage factors and support optimal material selection.

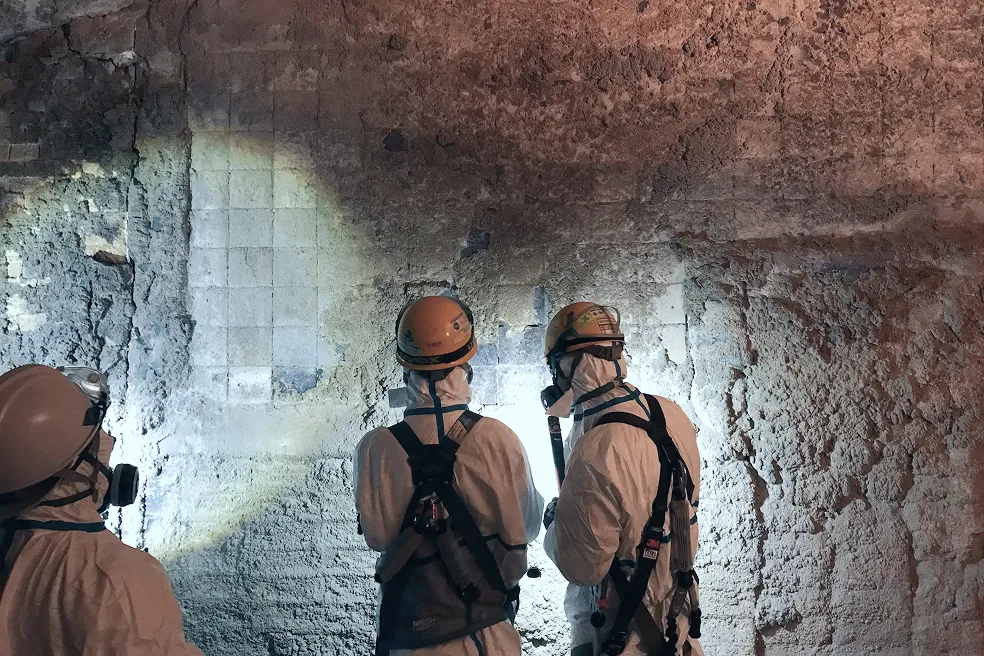

07.Refractory Inspection and Diagnosis

- Glass

- Incinerator

- Aluminum

- Cement

We investigate the health of refractories used in onsite equipment and provide detailed reports.

Upon customer request, we combine this with used refractory analysis to support improved safety and efficiency of equipment.

In the future, we are preparing to introduce unmanned inspection technology using drones, aiming for even faster and safer service delivery.