Engineering Fine Ceramics

Based on our cultivated technology over many years in the field of high-temperature materials, we in AGC Ceramics have developed various types of fine ceramics.

Here, we introduce our various types of fine ceramic materials those are excellent in heat resistance, corrosion resistance and abrasion resistance and usable for various applications including the environment, energy and electronic industries.

CERAROI-C (silicon carbide)

CERAROI-C is pressure-less sintered dense silicon carbide and re-crystallized silicon carbide with high fracture toughness achieved through our own unique material technology. It has various properties such as high strength, high hardness, high rigidity, high thermal conductivity, low thermal expansion and chemical resistance.

CERAROI-C is pressure-less sintered dense silicon carbide and re-crystallized silicon carbide with high fracture toughness achieved through our own unique material technology. It has various properties such as high strength, high hardness, high rigidity, high thermal conductivity, low thermal expansion and chemical resistance.

CERAROI-N (silicon nitride)

CERAROI-N is silicon nitride(Si3N4), and highly reliable for their strength and fracture toughness. This material is utilized as molten nonferrous metal-related parts such as protection tube for thermo-couple for aluminum, and nuclear energy-related parts.

CERAROI-N is silicon nitride(Si3N4), and highly reliable for their strength and fracture toughness. This material is utilized as molten nonferrous metal-related parts such as protection tube for thermo-couple for aluminum, and nuclear energy-related parts.

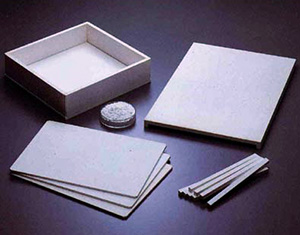

LOTEC-M (cordierite)

LOTEC-M is cordierite created by AGC Ceramics's original electro-fused synthesis technology. Making use of the property of low-thermal expansion, it is utilized as tools for heat-treating parts,

electronic-related parts and a heat-expanding adjusting filler for electronic parts.

LOTEC-M is cordierite created by AGC Ceramics's original electro-fused synthesis technology. Making use of the property of low-thermal expansion, it is utilized as tools for heat-treating parts,

electronic-related parts and a heat-expanding adjusting filler for electronic parts.

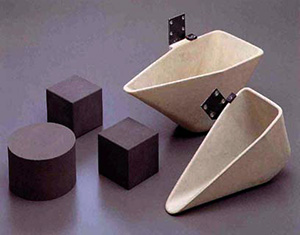

LOTEC-T (aluminum titanate)

LOTEC-T has properties of high resistant to thermal shock, and does not react with molten metals such as aluminum or zinc, nor get wet. By utilizing these properties, LOTEC-T is used as an industrial heat-resistant material. We also have machinable ceramics that can be processed into a wide variety of shapes.

LOTEC-T has properties of high resistant to thermal shock, and does not react with molten metals such as aluminum or zinc, nor get wet. By utilizing these properties, LOTEC-T is used as an industrial heat-resistant material. We also have machinable ceramics that can be processed into a wide variety of shapes.